Fighter

posted this

21 September 2025

Hi Jagau,

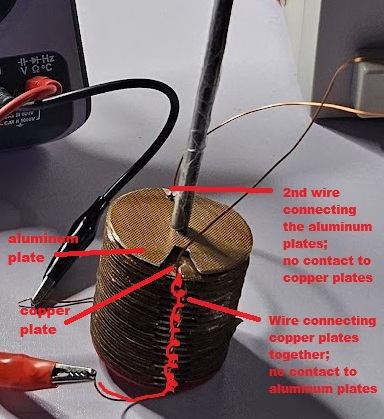

In your first photo that was just a temporary support while I've made the holes in plates so I've made sure the holes are aligning with each other; see the two thick double wires going through the holes - one going throught the holes of the copper plates and the other one going through the holes of the aluminum plates.

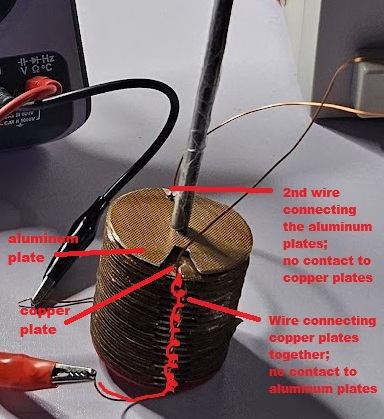

This is the assembled customized capacitor (not complete, more plates should be added but I have the issue of random contacts between copper plates and aluminum plates):

The carbon fiber rod in the center is just for mechanically fixing and aligning all the plates, it's not making electrical contact with the plates (I isolated it with scotch tape).

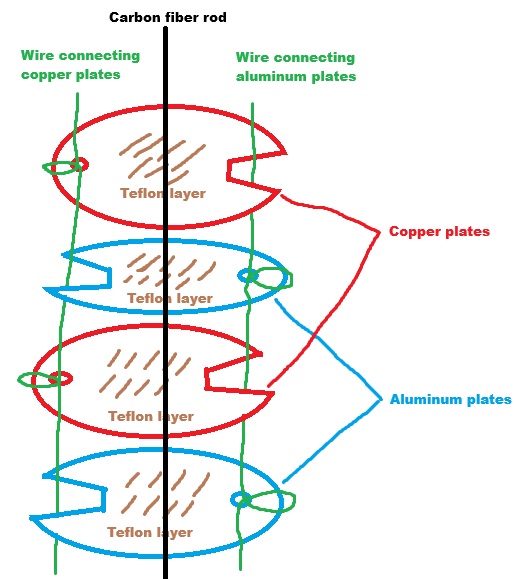

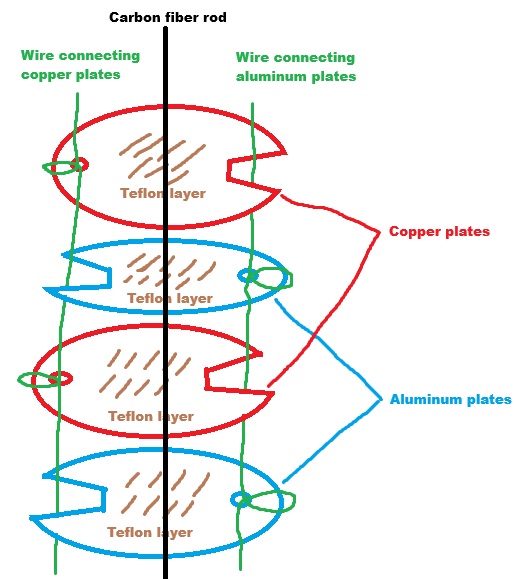

I just made a hand-made sketch with just two copper plates and two aluminum plates and the two wires to show how one wire is connecting the copper plates and another wire is connecting the aluminum plates:

When looking at the sketch please keep in mind that:

- the v-shaped cuts in the copper plates are made to avoid their electrical contact with the wire connecting the aluminum plates;

- the v-shaped cuts in the aluminum plates are made to avoid their electrical contact with the wire connecting the copper plates

This was the solution I've came with to avoid electrical contact between copper plates and aluminum plates but to still be able to electrically connect the copper plates together and the alumium plates together; that's why all that heavy and time-consuming work was necessary.

I don't know if I explained well, if something is unclear don't hesitate to ask me.

Fighter

| "If you want to find the secrets of the universe, think in terms of

energy, frequency and

vibration." |

|

|

Nikola Tesla |